In the realm of machine building, the pursuit of differentiation in a fiercely competitive global market is our constant challenge. As the sands of technology shift beneath our feet, we, as machine builders, strive to meet the ever-growing demands of the packaging industry.

Our mission: to deliver Vertical Form Fill and Seal (VFFS) machines that harmonize high production output, unwavering reliability, top-notch product quality, with minimal manpower requirements and maintenance costs. In this journey, we ensure our machines possess the versatility to adapt seamlessly to varying bag dimensions and intricate designs.

The VFFS Revolution: A Symphony of Automation

VFFS machines are the unsung heroes of modern packaging. These automated assembly line packaging systems are the backbone of packaging liquids and solids, revolutionizing the way we prepare products for the market. VFFS machines come in two flavors: intermittent and continuous motion. Intermittent motion machines are our answer to applications where speed isn’t the critical factor.

Demystifying the VFFS Machine Process

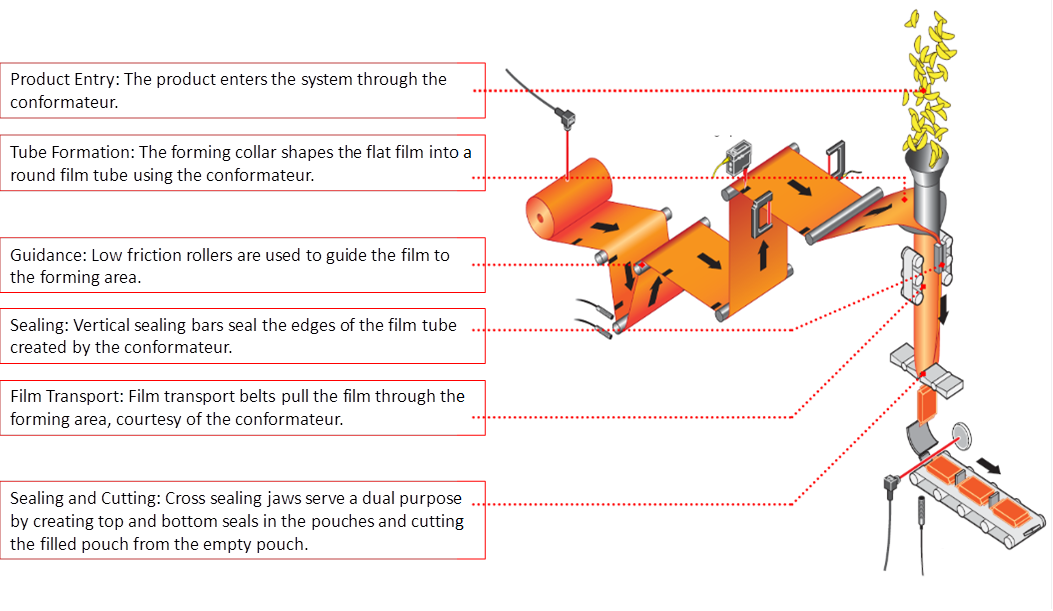

Let’s demystify the intricate dance of the VFFS machine.

From the unwinding of a roll of film, it elegantly forms into a tube over a conformateur. Vertical sealing bars perform their magic, crafting a secure vertical overlap seal, while horizontal sealing bars in the cross jaws fashion a reliable bottom seal.

The drama unfolds as the pouch is filled with precision, ensuring the right amount of product is placed consistently, thanks to the precision scale or an auger. As the film transport belts feed the film tube, the perfect length is reached. It’s at this moment that the filled pouch gets its top seal from the horizontal sealing bars, while a sharp knife in the cross jaws cuts the pouch free.

For pre-printed film, a registration sensor takes the stage, maintaining the print position with perfection.

Challenges Met: Meeting Expectations Head-On

End-users have a set of expectations, and we’re here to deliver:

– Productivity: We optimize the packaging process, achieving maximum machine speed, maximizing throughput with the highest quality, and shortening recovery time.

– High performance: We meet strict accuracy requirements at high machine speeds, even with variable bag lengths.

– Flexibility: We’ve put an end to manual adjustments of film registration sensor positions by introducing a software adjustment scheme, dramatically improving changeover times.

– Ease of use: Despite machine complexity, our VFFS machines are designed to be easy to maintain and operate.

Machine Builders: Shaping the Future

As machine builders, we’re committed to crafting modular and scalable VFFS machines, where customers can mix and match machine functions to suit their specific applications. We’re standardizing mechanisms common to VFFS machines, making them easily redeployable with minimal modifications. This not only reduces design and development time but also significantly cuts costs, ensuring our machines are cost-effective.

The journey through the world of VFFS machines continues, elevating packaging efficiency, setting new standards for quality, and simplifying the process for all. With a keen eye for innovation and precision, we’re poised to make your packaging needs our top priority.

Join us in this journey to revolutionize your packaging experience!